Oct 20, 2021

A practical guide to managing safety stock in your supply chain.

Safety stock performs a big role in your supply chain and helps businesses avoid stock-outs and meet demand. How much safety stock do you need to optimize your inventory?

Inventory planners plan the stock your business needs for the future. Determining the appropriate inventory levels is one of the most essential and challenging tasks faced by inventory planners.

- If you carry too much inventory - you tie up cash in working capital.

- If you don't have enough inventory - you can experience stock-outs.

If you sell more stock than planned or if your suppliers are unable to deliver at the expected time, there is the risk that you will stock out and not be able to supply your customers. Can your business afford to stock out on the items that have a significant impact on your sales?

Experiencing stock-outs can leave your business vulnerable; you can either lose the sale, a customer, or both! With ongoing supply chain disruptions and unpredictable customer demands, you need an ‘insurance policy’ to help keep your supply chain moving forward.

Your ‘insurance policy’ = safety stock.

This guide will help you understand the importance of safety stock and highlights the necessary inventory inputs to consider when calculating the safety stock you need for your inventory.

Your customer is the lifeblood of your business so let’s make sure you never let them down.

We will explore the following topics in this guide:

- What is safety stock?

- Why does your business need safety stock?

- What happens when you experience stock-outs?

- What inputs must you consider when selecting your safety stock levels?

- Your inventory policy and safety stock.

- What factors should you consider when identifying your safety stock?

- The impact of having too much safety stock.

1) What is safety stock?

Quite simply, safety stock is the quantity of extra stock or buffer stock you need available in your warehouse so that you can meet demand and avoid the effects of stock-outs. Inventory safety stock acts as a buffer when you reach the end of your replenishment cycle, and the challenge is knowing how to calculate the correct safety stock levels required for the necessary items. You don't need safety stock for every single item!

Inventory tip: Your safety stock levels can’t guarantee you will never experience stock-outs. Safety stock will help you deal with unexpected demand and or late supplier deliveries.

2) Why does your business need safety stock?

Safety stock ensures your customers always get the stock they want. While that may sound simple, there are two variables you need to consider before you calculate the safety stock you need. First up, the items that your customers want will either have a predictable or unpredictable supply. The items that are difficult to forecast accurately will require more safety stock. Items that are more predictable, will be easier to forecast and won't require as much safety stock. Secondly, if your items arrive late you will need more safety stock and then the reverse, you will need less safety stock if your items arrive earlier than expected.

Holding the right level of safety stock will help your business:

- Mitigate the risk of stock-outs.

- Maintain ongoing customer loyalty.

- Improve your sales.

Inventory tip: Develop healthy two-way communication with your suppliers. Understand their challenges and if they are going to extend their lead times. By sharing your forecast of the purchase orders you are projecting to place over the following months with your suppliers, they too will better understand the demands you need to meet and by when. This will help you keep your customers informed if you know your supplier is struggling with extended lead times or experiencing a shortage of raw materials.

The purpose of safety stock is to safeguard your business from two significant inventory risks:

- Forecast risk: You won't always know what your customers will need, so you can’t guarantee your forecasts will be 100% accurate.

- Supply risk: Your suppliers also experience disruptions that prevent them from delivering on time and in full.

Inventory Tip: The people who need to add input into your forecast are the people who know your customers! Use market intelligence to help ensure your forecasting is accurate.

For every action, there is a reaction. If you are a retailer or distributor and your customer has ordered stock which you don’t have on hand, what’s the reaction?

- Why have you stocked out? You may have experienced high demand and or, failed to factor in the right amount of safety stock needed for that specific product when you placed your order.

- How does your customer react? Frustrated and may reconsider working with you in the future.

- What happens to your sales? If your customer is not happy to wait for the stock, you can lose that sale and future sales from the customer.

Inventory Tip: Communicate with your customers regularly. Learn what is happening in their market and how their competitors are doing. The more you know about your customers and what they need, the easier it is for you to ensure you can supply them with the items they want on time.

3) What happens when you experience stock-outs?

Without customers, your business will fail. In today's fast-paced competitive economy, the consumer wants instant gratification and consistent communication regarding the status of their order, regardless of the industry you are serving.

Stock-outs also affect your internal processes. Your team will often spend additional hours trying to establish why you are stocking out on certain products. As a solution to running out of stock, inventory planners will usually have to:

- Place emergency orders on their suppliers.

- Select a faster, less cost-effective delivery option. [for example, using air freight]

- To keep the customer happy, buy the product from a competitor - even if it means selling the product at a loss!

What does it all mean for your business?

To minimize the impact of stock-outs, you need visibility of what's happening with your inventory. Working from an inventory management solution that provides a dashboard that measures your inventory KPIs, such as identifying the items that will stock out before the next delivery arrives, will allow you to take action quickly to meet demand at minimum cost.

“NETSTOCK recognizes that you can’t look at every single item every day, so it focuses on the most important items. The dashboard gives you a high-level view of total stock holding, excess stock, stock-outs, and potential stock-outs. We can quickly see where the pain points are and what action we need to take.” Crazy Aaron Enterprises, Inc, USA.

When you experience a stock-out, your customer will typically do one of the following:

- If they want stock from the same brand, they may look for another supplier that can provide this to them.

- They may consider switching brands entirely.

- If they are loyal to the brand, they may look at an alternative model, size, color, etc.

- If they are passionate about the brand, and in no particular rush, they may wait until the stock is available.

- There is a point where customers will no longer tolerate stock- outs and switch to another brand.

- An online customer may abandon their shopping cart altogether and all the other items in the cart. You will most likely lose the whole basket of products they intended to purchase.

An extract from the RIS online article cites, “Even before the pandemic, out-of-stocks were a staggering $1 trillion problem, and nearly three-quarters (71%) of retailers named “lack of real-time inventory visibility” as a top obstacle to overcome.”

4) What inputs must you consider when calculating your safety stock levels?

If you manage a large inventory of items spread across a few locations, adopting a "one-size-fits-all" approach to calculating your safety stock will still result in some items stocking out and some in excess stock. So, how do you set the appropriate safety stock levels for each item?

Apart from your target fill rate, the other critical inputs to the safety stock calculation are:

- Forecast: an accurate forecast is when the sales team provides market intelligence from their top customers. The more you under-forecast, the more safety stock you may need.

- Replenishment Cycle: when and how much inventory you buy. The shorter the cycle, the more safety stock you may need (frequent, small deliveries are riskier).

- Lead time: the number of days it takes for the stock to arrive in the warehouse after placing the orders. The longer the lead time, the more safety stock you may need.

- Forecast risk: taking into account your forecast wont always be 100% accurate, you need safety stock to buffer for these inaccuracies.

- Supply risk: understanding that your suppliers are not always reliable, if your supplier delivers late you will need safety stock to ensure you can deliver to your customers as promised.

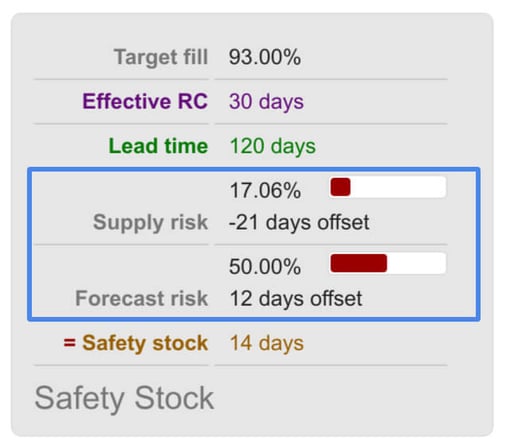

A snapshot of how the NETSTOCK app automatically calculates safety stock.

A snapshot of how the NETSTOCK app automatically calculates safety stock.

When setting the safety stock level for each line item, consider the following:

- The desired or target availability (service) level

- The accuracy with which the item is being forecasted

- Length of lead time

- The reliability and accuracy of the lead time

- The replenishment cycle

- The review cycle. [The frequency in which items are reviewed for ordering purposes.]

- The service lag time. [Is the item required to be "on the shelf," or is 48-hour delivery acceptable?]

Inventory tip: When you reduce your safety stock levels, you also reduce the overall inventory investment, likely impacting your availability levels and fill rates.

5) Your inventory policy and safety stock.

An inventory policy acts as a framework for effectively managing your inventory by balancing your working capital with your desired service level to your customers, known as your target fill rate.

Your policy provides the set boundaries in which you can manage your inventory. For each stock item, you will need to factor in the supply and demand risks and the safety stock levels when setting your inventory policy for your business.

Sometimes, you can have it both ways: Better service levels and saving money on stock.

By investing your money in the correct items and taking investment away from the less important items, you can save money and provide better service levels to your customers.

The way to flex your inventory policy is also through safety stock. Your service level will be better if you carry more safety stock on an item, but that requires you to have more cash tied up in your warehouse. The less money you invest in safety stock, the better your cash flow, but your service levels may suffer as a result.

An inventory policy acts as a framework for effectively managing your inventory by balancing your working capital with your desired service level to your customers, known as your target fill rate.

Your policy provides the set boundaries in which you can manage your inventory. For each stock item, you will need to factor in the supply and demand risks and the safety stock levels when setting your inventory policy for your business.

Sometimes, you can have it both ways: Better service levels and saving money on stock.

By investing your money in the correct items and taking investment away from the less important items, you can save money and provide better service levels to your customers.

The way to flex your inventory policy is also through safety stock. Your service level will be better if you carry more safety stock on an item, but that requires you to have more cash tied up in your warehouse. The less money you invest in safety stock, the better your cash flow, but your service levels may suffer as a result.

6) What factors should you consider when identifying your safety stock?

You need to classify your inventory.

You have 100s or even 1000’s of SKUs in your warehouse, and not every item will have the same demand levels. Some items play a more important role in your business than others. When you classify your inventory, you identify your:

- obsolete items: items you don’t plan to stock anymore

- non-stocked items: items that you only order on request

- stocked items: your active stock

Classifying your stocked items using an ABC analysis allows you to focus your time and prioritize your resources on your most important stocked items. Your stocked items are classified according to their relevance or importance and sales velocity using a classification matrix. Knowing which items are high-value, fast-moving, you can establish which items may require safety stock. If your high-value, fast-moving items have unpredictable demand, you may need higher safety stock levels for those items.

What does this mean for your business? By classifying your items, you invest your money in the correct items and take investment away from the less important items.

Know your supplier’s history.

Know your suppliers and analyze their delivery history. Review how often your suppliers delivered in full or only part and remove any irregularities that could skew the results. For example, the items air freighted in on special orders or orders with an unexpected delay.

Have accurate sales and previous forecast history.

Analyze your sales history against your previous forecasts to determine your level of accuracy and predictability. Don't only look at the last month's data as the purchase decision is often made months ahead of that. Measure from when you had stock of the item to sell rather than when the product was added to the master list. Take any staff or computer overrides into your forecast measurement into account, as it's the combination that results in what you end up purchasing. Consider the stock item's risk profile and the forecast accuracy to give you the safety stock you need to act as a buffer and help your sales team.

Review target fill rate.

Your fill rate refers to the percentage of customer demand you can meet with your current stock on hand without placing backorders or missing a sale. To buffer against potential uncertainties or disruptions, you would need an infinite amount of stock that most businesses are unlikely to afford. It would also be challenging to find space to store all this inventory. When determining your safety stock level, it doesn't help to use a fixed quantity either. This may result in being overstocked during part of the year and under-stocked at other times. Good inventory planning requires the ability to apply dynamic values.

Always review your safety stock levels because your risks change regularly:

- Your forecasts change

- Your supplier's risk changes

- Your business objectives change

Inventory tip: The target fill rate on your important fast movers needs to be higher than your slow movers -don’t be caught without having enough of your popular items!

7) The impact of having too much safety stock.

If you order too much safety stock you can land up with excess stock in your warehouse. Excess stock is costly to your business as it increases your overall inventory costs. You need to factor in additional money and resources to hold that excess stock, such as:

- Additional storage space

- Additional insurance

- Additional labor and admin

- Potential loss of products due to damage or theft

In a complex world, planning your inventory optimally requires the best available inventory management tools.

To know what stock items to order starts with knowing what you are planning to sell. While the supply chain continues to experience huge shifts, using a spreadsheet for your planning and replenishment requirements can place your business at risk.

Given that calculating safety stock requires several inputs, are you confident you can meet demand, avoid stock-outs and continue to make more sales?

Investing in a demand planning solution like NETSTOCK will give you the visibility to create accurate forecasts, order recommendations, and the correct safety stock requirements needed for your business. Safety stock is calculated on each item's classification. If your supplier becomes unreliable, the supply risk will automatically escalate, and NETSTOCK will automatically increase the safety stock level you need for that item. Simple and accurate.

Let NETSTOCK help you accurately manage the right safety stock you need.

Written by The Inventory Mentor

The Inventory Mentor provides thought leadership insights and industry trends for the supply chain industry.