Jul 01, 2021

Do you know the real cost of inventory?

Inventory and its holding costs have a direct impact on your cash flow. Understanding these costs can improve your cash flow and help your business navigate uncertainty.

Having an accurate view of your stock holding costs will allow you to identify areas where you can potentially decrease costs.

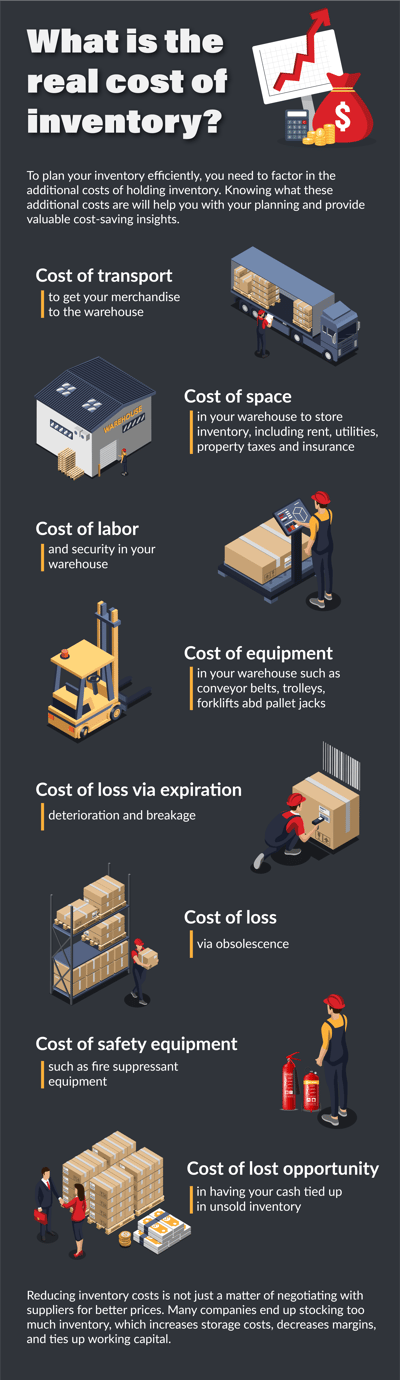

The total cost of your inventory amounts to all expenses incurred in storing your items and is generally tied to your warehouse and other intangible costs.

Here are eight additional costs of holding inventory that you need to factor into your inventory planning and tips on where you can save costs.

Nine tips to reduce inventory costs:

1.) Avoid minimum order quantities from suppliers.This is a supplier’s way to offload stock onto their retailers and wholesalers, reducing their costs while increasing yours. If there is no way to avoid this, see if you can form alliances with other companies that require the same stock as you. Splitting the orders can go a long way to reducing your inventory costs. Alternatively, you could offer a forecast of future orders as a commitment to your supplier, who may agree to allow smaller quantities.

2.) Know your reorder point.There is a fine line between ordering too much (risking obsolescence) and ordering too little (risking stock-outs). Once you have historical data, finding optimal reorder points for your items should be less of a gut instinct and more about data-driven insights.

3.) Organize your warehouseTo ensure staff efficiency when it comes to picking stock, you need a warehouse that runs effectively. For example, place your fast-moving items in the front of your warehouse – this optimizes your pick, pack, and ship process.

4.) Get rid of obsolete stockKeeping stock that isn't selling probably costs more than what you paid for the items in the first place. Instead, try a promotional campaign, either creating a special offer or bundling the product with a fast-moving item. However, be sure not to record this as a ‘normal’ sale that will trigger the reorder cycle. If none of these suggestions work, donate the items or write them off.

5.) Order your inventory “Just in Time [JIT]”“JIT ordering” does not suit all companies. It’s a process that requires you to have a strong relationship with your suppliers and a good relationship with a reliable transport company. If JIT ordering doesn't work for you, you'll want to examine your demand planning process to make sure it's helping you run an optimized warehouse.

6.) Use consignment inventoryYou could offload consignment stock to your retailers in a wholesale situation and utilize their shelf space instead of your warehouse space. The only downside to this is your retailer won’t pay for this upfront, so compare the cost of your floor space to the cost of managing consignment levels.

7.) Reduce lead timesShorter is better when it comes to lead times because it allows you to keep less safety stock and helps you cut down on excess stock. Shorter lead times can make it possible to reduce the size of your warehouse and your inventory value overall.

8.) Monitor your Key Performance Indicators [KPIs]To understand your business, you have to utilize measurements that give you visibility into your inventory. For example, you can discover how healthy your warehouse is by measuring KPIs and monitoring your inventory turnover, cycle times, and fill rates. . Then, compare your numbers with industry averages to assess how well you manage your business and warehouse. These insights will assist you in reducing your inventory and other related costs.

9.) Use accurate forecastsForecasting demand through accurate and intelligent reports allows you to order just enough to meet your demand throughout the year for every season. You can accurately determine what products you need to discard and what you need to reorder. Your forecasts should use historical data to produce more helpful purchase orders.

You need full visibility of key metrics to measure your inventory holding.

You can only manage your inventory costs if you can measure your inventory – and the only way to measure your inventory is to have an automated and integrated system in place.

You can implement smarter, better inventory policies that cut your costs – and it all starts with accurately measuring your inventory.

Too many businesses hurt their profits by using outdated tools and management tactics to run their warehouses.

Using a demand planning tool that leverages your ERP data will allow you to focus on optimizing your inventory and tighten up your warehouse.

Implementing an inventory management solution doesn't have to be costly. Learn what your estimated ROI will be if you implemented NETSTOCK in your business.

Written by The Inventory Mentor

The Inventory Mentor provides thought leadership insights and industry trends for the supply chain industry.