Dec 04, 2019

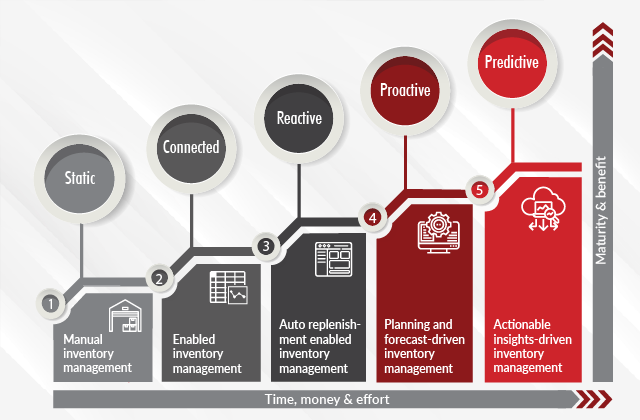

Where is your supply chain business on the inventory maturity curve?

The foundation of any supply chain business is their Inventory. As with any "foundation," if it’s not healthy and stable, the cracks will start to appear. Before long, you will have severe problems on your hands, which take away from the little time you have in dealing with emergencies. Better inventory management means freeing up, not only working capital to grow your business, but also giving you more time to do what’s important. Such as reducing excess stock and shortages, leading to more sales and happier customers with reduced pressure on deliveries and logistics and with increased inventory turns.

The first step to improving your Inventory management processes is to understand where you are on the inventory maturity curve. Take a look at the various stages below. It’s not so much as where you would like to be on this curve but where you NEED to be in order to survive in your market and be a part of the competitive landscape.

Level 1 – Manual Inventory management (Static)

You are at Level 1 when:

- Your Inventory data is managed in spreadsheets.

- There may be a repository for the sharing of information between team members.

- Data Analysis is mostly a manual and time-consuming task.

- No ability to gather data intelligence to provide predictive or proactive capabilities.

Challenges experienced at this level:

- Your staff spends more time ‘fighting fires’ than being proactive.

- Your data is static and becomes instantly outdated.

- There is no intelligence from an ERP solution to assist with supply and demand.

- There is no data to provide predictive analysis.

- No monitoring or built-in Alerts to signal shortages, excess, or stock availability at other locations.

- It's challenging to obtain a single version of the truth as multiple versions/systems exist.

- There is duplication of data resulting in the inefficient use of staff’s time.

Level 2 – Enabled Inventory (Connected)

You are at Level 2 when:

- You are still utilizing spreadsheets, but you’ve spent much time doing custom-built macros and databases to organize the data.

- These systems provide some visibility into your current inventory levels.

- Still mostly manual data analysis.

- You may have a single repository for sharing information between employees.

- No predictive or proactive insights.

Challenges experienced at this level include:

- Limited functionality

- Lack of AI and BI data to effectively manage your inventory

- Macros in spreadsheets are sensitive to change and break easily

- Lack of flexibility - new products and plans cause havoc and are impossible to plan

Level 3 – Auto replenishment enabled Inventory (Reactive)

You are at Level 3 when:

- You have visuals on dashboards, scorecards, and other KPI’s.

- Your supply chain data is stored in an ERP system.

- A repository of data intelligence now exists to enable quicker decisions to be made.

Challenges experienced at this level include:

- BI tools within your ERP are not explicitly designed for Inventory management and do not take advantage of industry best practices.

- They require IT and other resources to make any small changes and to develop and maintain.

- There is still no predictive or proactive capabilities.

- Limited collaboration.

Level 4 – Planning and forecast - driven Inventory Management (Proactive)

You are at Level 4 when:

- Your inventory data is maintained and analyzed using analytics software specifically for inventory management.

- You now have predictive analytics or even artificial intelligence tools to enable you to prioritize tasks effectively.

- Your inventory control data is in your ERP and other data sources.

- Connects your people, sites and disparate ERP systems to pull all inventory data into one place

Challenges experienced at this level may include:

- Change management to a more complete solution may cause issues

Level 5 – Actionable Insights - driven Inventory Management (Predictive)

You are at Level 5 when:

- Your Inventory data is maintained and analyzed using analytics solutions with features designed explicitly for Inventory optimization

- Predictive analytics, AI or machine learning that enables you to prioritize your most critical inventory issues.

- Connects multiple people, sites, algorithms, and disparate ERP systems to pull all inventory data into one place

Optimally, level 4 or 5 is where you would want to aim. These levels represent the best of both the present and the future of the supply chain and incorporate AI, BI, Machine Learning, IoT, and more. Tragically the majority of companies are still fumbling about in the first 2 Levels of the curve. You will find that as you climb the curve the business benefits you will experience include:

- Balanced inventory - more cash

- Improved availability - increased sales

- Staff productivity improvements - creating the capacity to do more

- Improved Forecasts

- Provides visibility of what needs attention

In conclusion, optimize your inventory through effective and efficient solutions or risk leaving money on the table or down the drain. The exciting part of implementing a robust Inventory management solution is that you can sometimes see an ROI even after the 1st month! - this will be sure to impress your stakeholders.

Written by Tony Sinton

Tony is the group CEO and co-founder of NETSTOCK, the first fully cloud-based inventory management solution. Tony provides strategy on supply chain management and has spent the last 30 years enabling thousands of companies across the world to better manage their inventories.